Ceramics

![]()

![]()

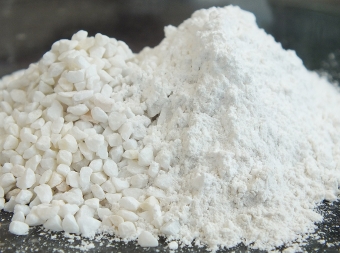

These are produced by crushing and consequent grinding of silica sand to the required grain size. Their quality and especially volume homogeneity is ensured thanks to the high-quality and modern equipment in production. The flours are very often used as sealants, fillers in cements, and for interior and facade paint production. Our silica flours are applied in the production of porcelain, sanitary equipment, ceramic tiling and glazes.

Potassium water glass from the chemical plant Rudniki is an aqueous solution of potassium silicate that is produced from high quality Grudzeń Las silica sand and alkaline fluxes. This water glass is characterized by the modulus, which is the molar ratio of SiO2 / K2O ranging from 2.6 to 3.2.

It is used for wood, stone and masonry impregnation or for the production of paints and sealants in the construction industry. Potassium silicates also have a positive effect on plant physiology. They strengthen the cell walls and create a protective barrier against germs.

Dolomite gravels and flours are characterised by a high CaMg(CO3)2 content (min. 90 %) and a low CaCO3 content (only max. 10 %), with a low Fe2O3 content. Dolomite aggregate is crushed and ground into gravels and flours of various grain sizes at Grudzeń Las. These are mostly applied in glassworks, where the calcium carbonate is used as a stabiliser. It also modifies viscosity and increases the durability of glass. Another major area of application is in the construction industry.

In cooperation with Grudzeń Las sand plants, we can develop products to match specific requirements of our customers.

Our kaolin is obtained through the wet removal of clay components from silica sandstone during silica sand production. This is followed by a multi-step process of dehydration in settlement tanks and a final compression. As a result, we get kaolin sheets with the moisture content up to 25 %. Our strength lies in the colour scale, ranging from a pale beige to red tones. It is primarily intended for the ceramic industry, specifically for the production of porcelain, sanitary equipment, ceramic tiles and glazes.

info@h-glost.cz

info@h-glost.cz

+420 544 544 440

+420 544 544 440