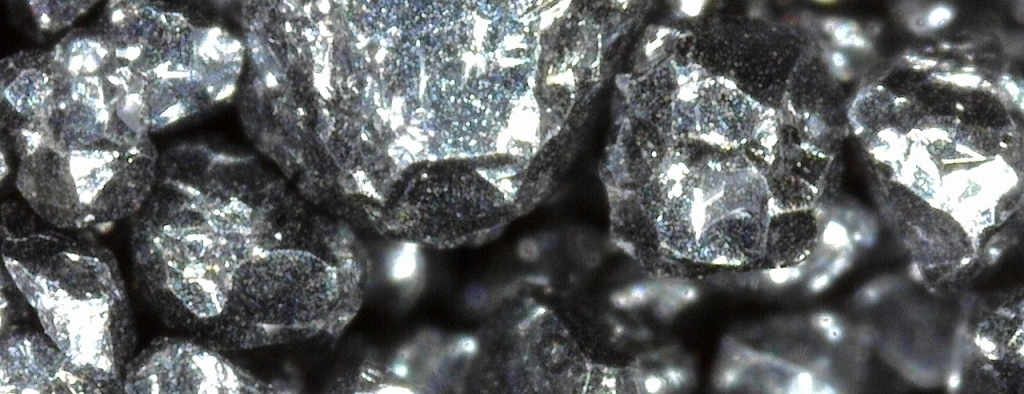

Chromite sand

This is a refractory material (more than 1800 °C) intended for places exposed to high heat in the casting production, and not just in steel casting. Compared to silica sand, it differs in its higher cooling effect, penetration resistance and lower thermal expansion. However, its relative density is higher. It is also used in the glass production where glass is tinted, as well as in the production of ceramics.

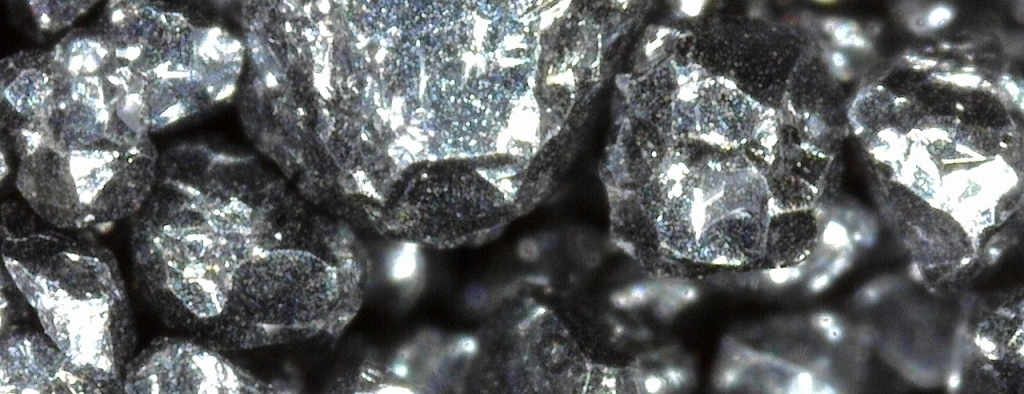

Dolomite gravels and flours

Dolomite gravels and flours are characterised by a high CaMg(CO3)2 content (min. 90 %) and a low CaCO3 content (only max. 10 %), with a low Fe2O3 content. Dolomite aggregate is crushed and ground into gravels and flours of various grain sizes at Grudzeń Las. These are mostly applied in glassworks, where the calcium carbonate is used as a stabiliser. It also modifies viscosity and increases the durability of glass. Another major area of application is in the construction industry.

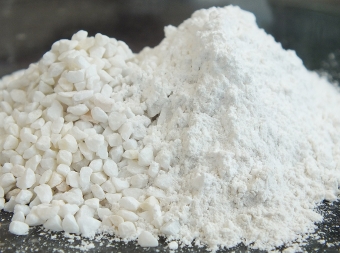

Kaolin

Our kaolin is obtained through the wet removal of clay components from silica sandstone during silica sand production. This is followed by a multi-step process of dehydration in settlement tanks and a final compression. As a result, we get kaolin sheets with the moisture content up to 25 %. Our strength lies in the colour scale, ranging from a pale beige to red tones. It is primarily intended for the ceramic industry, specifically for the production of porcelain, sanitary equipment, ceramic tiles and glazes.

"It is our endeavour to satisfy every customer,

so do not hesitate to contact us with even highly specific requirements“

info@h-glost.cz

info@h-glost.cz

+420 544 544 440

+420 544 544 440